To continue my series on the American Milk-fed veal industry, I’m going to write about my experience in the veal processing plants. In this series, I’ve already written an overview of the veal industry and about how the calves are fed and raised.

On our tour, hosted

by the American Veal Association, we

were invited to visit two veal processors in the Philadelphia area. We had

breakfast with Wayne Marcho, who told us the story of Marcho Farms. He expanded his

business from a few veal calves that he had in his boyhood into a company that

employs over 200 people and contracts with veal farms in 5 states. He likes to

say it’s a 4H project that ‘got out of hand.’

|

| A photo of Mr. Catelli's father. I love the history in the meat business. |

As a meat scientist, I was excited to get to see a new type

of processing plant, but what I saw didn’t surprise me in the least. Just like

all the meat processing plants I’ve been in, these plants had the highest

standards in animal welfare and were immaculately clean and sanitary. They are

operated under USDA

inspection with their required HACCP plans to ensure that they produce a

safe and wholesome product.

We observed harvest at the Marcho Farms plant, and, as with

most large processing facilities in the US, Dr.

Temple Grandin helped to design and approved the holding pens and live

animal handling equipment. The animals are showered with water when they unload

off the truck and rested in pens. They are calmly moved to harvest only by

employees specially trained in live animal handling. The animals were stunned

to render them unconscious and proceed through the process using humane and

sanitary procedures just as is done in meat processing plants of all species.

I didn’t have any

doubt that the harvest process would be clean and humane because I know the

meat industry, and I know the people in it are committed to doing the right

thing. Now I can say that I’ve seen it with my own eyes.

|

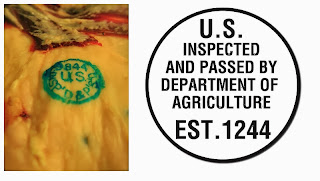

| A USDA inspection stamp on a veal carcass at Marcho Farms |

Although we were not

able to see the harvest side of the Catelli Brothers operation, Mr. Catelli

shared that their live animal handling areas are monitored by a third-party animal

welfare auditing company. They use video to view their entire process 100%

of the time they are in operation.

Marcho Farms uses a lactic acid wash on the carcasses at

various stages in the slaughter process to help keep bacteria from attaching to

the meat. USDA inspectors observe the live animals and the whole harvest

process. They will also look over each carcass and their organs for signs of

disease or contamination. The inspector will mark each carcass with an

inspection stamp of edible ink.

The carcasses are

washed with 180°F water and individually bagged in plastic to eliminate cross-contamination.

After chilling 48 hours in a cooler they are graded and cut up.

The calves

weigh about 500 pounds and have carcasses that range from 250 to 300 pounds.

|

| You can see the size of the veal carcasses at Marcho Farms. This man is about 6-foot tall |

Veal grading

Just like beef,

veal has USDA

grades assigned to the carcasses by a USDA grader. Veal carcasses may grade

Prime, Choice, Good, Standard, or Utility. Grades are decided based on the

conformation of the carcasses (ratio of muscle to bone and fat) and the color

of the lean. The grader evaluates each

carcass and designates their grade with a stamp of purple, edible ink.

Marcho Farms also

participates in a USDA Process Verified Program called Butcher’s

Block Reserve. It has qualifications for Quality grade in addition to

ribeye size and lean color. The USDA grader evaluates each carcass and

certifies the ones that meet the specifications for the program. It’s kinda

like Certified

Angus Beef for veal.

|

| At Marcho Farms, USDA graders stamp veal carcasses with Quality Grade or Butcher Block Reserve stamps based on lean color, ribeye size, and conformation (muscling). |

Fabrication

In the meat business,

we use the term ‘fabrication’ to reference the trimming and cutting up of the

carcasses, so it’s really the opposite of ‘fabrication’. But, that’s the tradition.

|

| Employees wear white frock and aprons, disposable sleeves and gloves when handling and cutting the veal. |

Just like in all meat processing facilities, the plant is

washed top to bottom every day, and company employees and USDA check the plant

for cleanliness before they get started. Anyone entering the plant is required

to wear clean frocks, hairnets, and hard hats. We had to wash our hands every

time we entered, even though we weren’t going to touch anything. Employees who

work with the meat wear plastic gloves and sleeves that get changed several

times each day.

All of the cutting

and packaging rooms are kept at refrigerated temperatures. Several times

throughout the process, the veal cuts were sprayed with a blend of lactic and

citric acid to control bacterial growth. The veal cuts move through the plant

on cleaned, sanitized conveyor belts and in containers we call ‘lugs.’ The veal

cuts are packaged ready to set out in the store. Catelli Brothers was the first

company to provide case-ready veal and lamb. Once the cuts are packaged and

labeled, they are boxed and stored in refrigeration until they are shipped out.

Even the shipping dock is temperature controlled and the company places a

temperature recorder inside each truck to ensure the meat stays cold.

|

| Case-ready veal cuts at Catelli Brothers |

Mr. Catelli said that most of their veal takes less than 7

days from harvest to retail. That includes the carcasses being imported from

Canada! Freshness is very important in

the veal industry. Both Marcho Farms and Catelli Brothers said that they

are able to trace their veal from farm to fork.

Something I always

enjoy hearing about is the plant employees. These two plants employ over 400

people. It’s not easy work. These folks have to work on their feet in cold

temperatures wearing lots of protective equipment. But, they enjoy their jobs.

Many employees of both of these companies have worked there for many years. Mr.

Catelli introduced us to Phil, who has been cutting meat for 57 years.

Something I always

enjoy hearing about is the plant employees. These two plants employ over 400

people. It’s not easy work. These folks have to work on their feet in cold

temperatures wearing lots of protective equipment. But, they enjoy their jobs.

Many employees of both of these companies have worked there for many years. Mr.

Catelli introduced us to Phil, who has been cutting meat for 57 years.

As on the harvest side, nothing I saw in fabrication and

packaging surprised me. The process was clean and efficient. I have no doubt

that they are producing a safe and wholesome product. Please let me know if you

have any questions.

I wanted to share a few more pictures from the plant.

|

| Some meat loaf blend heading from the grinder to packaging in the Catelli Brothers plant. It contains veal, beef, and pork. |

|

| The carcasses at Catelli Brothers are harvested in both the US and Canada. So, the Canadian food safety system inspects the carcasses that are imported. |

|

| Carcasses at Catelli Brothers are split into two sides like a beef or pork carcass, whereas those from Marcho Farms are left intact like a lamb carcass. Each company does what works best for them. |

|

| When the meat cutter removes all the meat from the ribs like this, we say its ‘Frenched.’ These are Frenched veal racks waiting for the meat cutter to cut them into Frenched veal rib chops. |

|

| Veal shanks for Osso Bucco. |

|

| Veal cutlets. They have been tenderized. |