It seems so simple to just freeze something. You get meat

really cold, it lasts a long time. But, we all know it is not that simple. Lots

of questions arise with freezing. Questions about packaging, timing, size of

cuts, type of freezer, how to thaw it and what it does to quality, all come up

when freezing meat. So, let’s talk about them.

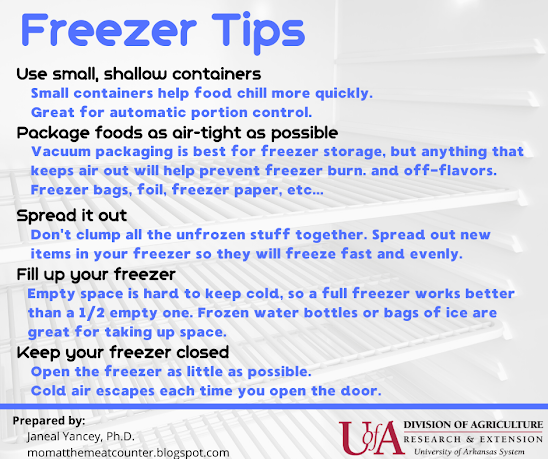

Packaging

Air is the enemy when you are freezing foods. Air allows for

oxidation and freezer burn. You want to keep air away from the surface of the

cuts in any way you can. For meat, the best packaging method when freezing is

vacuum. Some butchers use vacuum packaging, and you can buy vacuum packaged

cuts in the store. At home, you can buy a small vacuum packager and package

cuts yourself. If you freeze lots of meat cuts at home, that may be a good

investment for you.

Ground cuts that are packaged in chubs are essentially in

vacuum, but you may get a little spoilage in the edges, near the opening, but

most of the meat is protected from air.

The wax paper wrap that butchers use also works well in the

freezer. It keeps the air away from the cuts pretty well, but those packages

don’t last as long as vacuum. If you are buying a whole or half beef, it will

take a long time to go through it all. The packages will likely be in your

freezer for several months.

At home, you may want to try those freezer bags that zip

closed. Make sure that you squeeze as much air out of those as you can before

you close them. I try to fold them over and create a kind of seal around my

cuts. Packaging like that won’t last as long as vacuum or wax paper.

The worst way to package meat for the freezer is the foam tray

and overwrap like you see in the grocery store. That wrap is designed to allow

oxygen through (that’s

what makes the meat red), so freezing meat in those packages is just asking

for freezer burn.

Timing

The USDA guidelines state that you should consume frozen steaks, chops, and roasts

within 4 to 12 months of freezing. After that, it’s not as much a safety

issue, but eating quality. Juiciness, flavor, tenderness may suffer some if you

wait longer than a year. In vacuum packaging in a chest or stand up freezer,

whole muscle cuts last months and months.

Sausage, ground beef, and cooked meats don’t fare as well.

Grinding, cooking, and adding ingredients like salt are all things that make meat

oxidize more quickly and that can even happen in the freezer. USDA suggests

ground beef only be stored frozen for 4 months. Cooked meats, even less than

that (2-3 months).

Sizing

When you are putting fresh meats in the freezer for the

first time, you want them to freeze as quickly as possible. So, smaller cuts

and packages work better than large ones. If you like to buy things in bulk,

its best to repackage meats into portion-sized packages and freeze it in

smaller packages. Then, you can just take them out as you need them, rather

than having everything frozen together. I like to flatten ground beef packages

out so they will stack, and they will freeze faster.

Placement

Keeping with the concept of freezing meat as quickly as

possible, you want to make sure that you spread non-frozen things out in the

freezer when you first put them in there. Don’t put it all together in one

place. It will take a long time to freeze, and I’ve even seen things spoil in

the middle when they don’t get frozen completely.

Hopefully if you buy a large quantity of meat, it will come

frozen and you can put it all in the freezer at the same time, but if you need

to freeze a large quantity all at once, you may consider freezing it over

several days. Put some cuts in the

freezer and spread them out, let them freeze, and put in a few more cuts the

next day. Whole muscle cuts are ok for a few weeks in the fridge, so just be

aware of how long they’ve been stored. If you have to freeze cuts over a few

days like this, freeze the ground cuts first.

Which freezer is

best?

If you are planning to store frozen meat for several months,

its best to do so in a chest freezer or an upright freezer that is only a

freezer. The freezer in your fridge is ok for short term freezer storage, but

think about how often it is opened and every time the door opens, it loses cold

air. It’s best to have your meat stored in a specified freezer, even if it’s a

small one.

Thawing

A few years ago, I wrote a whole

post about thawing frozen meat, and in short, it’s best to thaw meat in

cold water or in the refrigerator. Cold running water works best. The microwave

is ok, too. You shouldn’t set meat on the counter to thaw. You don’t want it to

spend too much time in the danger zone of temperature where pathogens have a

chance to grow. Also, you can always

just cook your meat from frozen.

Can I thaw and

refreeze?

Yes. Some people are concerned about meat that has been

frozen, thawed and refrozen. As long as it stayed below 40°F

when it was thawed, food-safety wise, it should be fine. It may lose some

juiciness or have flavor issues from being thawed and refrozen, but chances

are, you won’t even be able to tell.

Whole muscle cuts like steaks, chops and roasts take this

treatment better than ground and processed cuts. Also, you don’t want to thaw

ground beef and leave it thawed for very long at all if you decide to refreeze.

At refrigerated temperatures, oxidation happens and it will be accelerated in

meat that has been previously frozen.

*If for some reason, your freezer loses power, don’t open

it. That will just cause you to lose the cold air that’s in there. The meat

will stay frozen for a while without power. When you get power back or get a

new freezer, check the temperature of the meat. Is it still frozen? Is it

thawed, but still cold (below 40°F)? If these are true, its probably ok

to just refreeze. If the meat is at room temperature or its been over 40°F

for 4-6 hours or more, you need to discard it.

What does freezing

do to quality?

The answer to this question is complicated. It depends. Some

aspects of quality may actually be improved with freezing. Researchers at South

Dakota State found that freezing beef actually improved the tenderness of beef

steaks compared to non-frozen. The ice crystals in the beef acted like tiny

little tenderizers.

For the most part, in whole muscle cuts under ideal

conditions, freezing doesn’t have much effect on other aspects of quality like

flavor and juiciness. Leaving something in the freezer for long periods or poor

packaging may result in flavor issues and loss of juiciness, though. Ground

beef and processed meats are more prone to flavor problems when they have been

frozen, but under good conditions (packaging and fast freezing), the benefits

of storing meat in the freezer out-weighs the problems.

I hope my post is helpful in answering your freezing

questions. Like always, please reach out if you have any questions or concerns.