|

| Me at Vallie's age. Living in bliss. |

We live in a country of plenty. I was blessed to have been

born into a family that never worried about hunger or where our next meal was

coming from. As a kid, I’m sure I crossed paths with kids who didn’t know if

there was going to be supper for them that night, but I was oblivious to their

problems. I wish all children could live in the bliss of a childhood I had, but

unfortunately, that is not the case.

In the US, 1 in 5

children are food

insecure, meaning that they lack access to enough food to maintain a

healthy lifestyle. I look at my daughter and it breaks my heart to think about

the parents in my neighborhood who don’t have the means to provide enough food

for their children.

Globally, the numbers are even grimmer. Hunger is the #1

risk of health in the world. More people die from hunger than AIDS, malaria,

and tuberculosis, combined. Every 7 seconds, somewhere in the world, a child

dies from malnutrition. I could go on and on about hunger, but that is not the

topic of this post.

By the year 2050,

it is estimated that the global population will rise to somewhere between 9 and 10 billion people. As people live

longer and more enriched lives, more people will enter the middle class and

will demand more food. It is estimated that the world will need to produce 100% more food than we do today to feed

those people. We are already using most of the land and resources that we have

for food production, so most of that increase in food production (about 70%) will have to come from

finding ways to produce food more efficiently.

Food may become a scarcity.

It is estimated that one

third of the food produced today in

the world is wasted. That is about

1.3 billion tons of edible food wasted or lost every year.

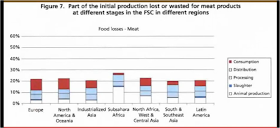

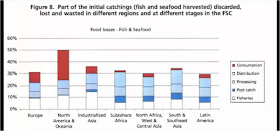

Last summer I attended a conference and a whole session was

devoted to food waste. Three speakers from the meat industry presented some

really eye-opening facts about food waste and what can be done about it. They

included Dr. Brian Smith from Hawkins, Inc., Dr. Brad Morgan from Pfizer Animal

Heath (now Zoetis), and Dr. Benjy

Mikel from Mississippi State University. I wanted to share some of their

information in a post.

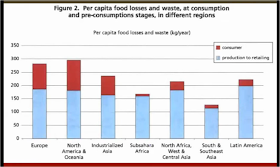

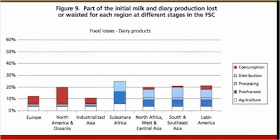

In developing countries, edible food is lost mostly during

the early and middle stages of food production, largely due to corruption and

lack of infrastructure. The challenges in those countries are in getting the

food to hungry people in a wholesome manner. Consumers in the developing world

waste very little of the food that reaches them.

In developed countries (USA, western Europe), food is largely

wasted at the consumption stage. Tons and tons of food in these countries is

discarded even if it is still wholesome and edible.

|

| My grandmother (in pink) with some of her brothers and sister. Part of the Greatest Generation, they did not waste food. |

In

the USA, food waste has increased 50% since 1974. That doesn’t surprise me when

I think about my parents’ and grandparents’ attitudes about food waste compared

to those of my generation. My grandmother was the youngest of 14 children and

was born in the first year of the Great Depression. Do you think she wasted

food? No way.

A few more facts about American food waste:

·

People in the USA waste approximately 1,400

kcal/person/day

·

3,000 lbs of food is wasted every second in

America, enough to feed 650 Americans

·

50% of leafy vegetables are wasted

·

33% of bread is wasted

·

12% of meat is wasted

·

22% of vegetables are wasted

The US could save roughly 2% of its total energy consumption in one year if we stopped

wasting food. That’s roughly equivalent to 300

million barrels of oil.

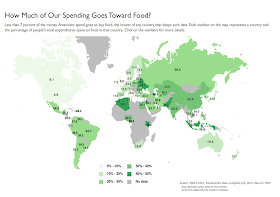

In

developed countries, we waste food because

we can afford to. In my grandparent’s time, they didn’t throw out food

because it wasn’t as cheap and accessible as it is today. In the US, only about

6.9% of our disposable income goes toward food. In China, they spend 32.9% of

their disposable incomes on food, in Brazil, 24.7%. Some countries are spending

over 40% of their disposable income on food.

If we were spending 6 or 7 times as much on our food, we

would probably be much less likely to waste it, but increasing the cost of food

in this country is not the answer. When you look at individual food stuffs, you

see that cheap foods, such as cereals, have much higher total waste and much

more waste at the consumer level than more expensive foods like oilseeds and

meat. You wouldn’t just forget about those $30 steaks you bought and let them

go bad in the fridge, but a $3 box of cereal is more easily forgotten. Of

course, shelf life plays a big role in food waste, too. Dairy products are

overwhelmingly wasted at the consumer level. I can’t count the times I’ve

poured 1/3 to ½ of my gallon of milk down the drain because it spoiled before

we drank it.

Not only do we lose resources that were used to produce food

that was eventually wasted, wasted food creates another problem in that all once-food,

now garbage must be transported and disposed of somewhere. Food waste in

landfills contributes to methane production and greenhouse gas emissions. According

to a story

by NPR, food accounts for 20% of the waste created in New York City. It

costs $100 million per year to haul it away.

What can be done?

Dr. Mikel told us that the world produces enough food to

feed everyone, even the 9 or 10 billion people that will be here in 2050. We

can work through programs like Heifer

International and USAID to help people

in the developing countries to have access to enough wholesome food.

AND, there are lots of ways to change our habits in this

country and be conscious about how much food we are wasting.

·

Controlling portions and minimizing food waste

at home is the first step.

·

Make a

shopping list based on what you

ate since you went to the store last.

·

Know how much you can eat at restaurants and

don’t be afraid to share a meal. In

the US, we tend to control our intake and overeating by leaving food on the

plate.

·

Make it a habit for small kids to share a meal,

either with you or each other. (This has been a new challenge for Vallie. She

is very opinionated about her meals.)

·

Understand use-by

and expiration dates. Most of the time these dates are just about food

quality and not food safety, meaning that the food may lose a little taste, but

it is still safe to eat. (For meat and dairy items, I would still stick close

to the freeze-by dates.)

·

Do some research on proper

handling and storage times for perishable foods. The internet is full of

good advice.

What is being done on

a corporate level?

ARAMARK – a company that supplies meals to students in

dining halls has eliminated trays from its dining halls on several campuses.

Remember that students pay to eat at dining halls by the meal, not by the food

item, so there is not a financial incentive to limit the food they pick up.

When they were not provided trays, students picked up less food. They were

probably still free to go back for seconds. Sounds like a small change, but at

the University of Alabama, they saved 6,000

pounds of solid waste per week by eliminating trays. ARAMARK has

implemented the program at 300 universities and saved over 15 million pounds of

food waste. They also saved water and energy by not washing all those trays.

TESCO

– a grocery store chain in the UK has taken several steps to help reduce food

waste. They changed the buy-one-get-one-free coupons to a buy-one-get-one-free next time coupon. Same savings for the

consumer, less likelihood of food being wasted. They have also implemented a

‘fresh indicator’ label on some of its food products to help consumers know

when the food is ok to consume. This label is based on time, temperature, when

the food was opened, and several factors and lets the consumer know whether the

food is fresh or not based on a traffic light label of green, yellow, or red.

Some countries are

taking an active role in helping to reduce food waste.

·

The United Kingdom has website to help consumers

control food waste called lovefoodhatewaste.com

as part of their Waste & Resources Action

Program (WRAP)

·

South Korea is the world leader in lowering food

waste. They accomplished this by taxing people for food waste. Consumers are

required to pay a fee for food waste. This measure has reduced food waste by

20% and saved $4.3 billion in US dollars.

When we think about food waste on a global scale and we see

figures like 1.3 billion pounds of food wasted, it seems overwhelming.

When I open my fridge and see forgotten leftovers, a wilted

bag of salad, and expired milk, I feel like a failure.

I am trying to approach food waste like I do any bad habit.

Little by little, I try to get better.

Some days, I will falter, but tomorrow, I will try to be better. Just

being conscious of the issue will be a big help.

What are some other steps we could take to waste less food?

I have a few more great links and figures:

My friend, Dr. Jude Capper, of Bovidiva

wrote a great post just yesterday on this same topic. Her insight is great.

The Food Network did a great special on Food Waste called The

Big Waste. It is definitely worth watching!

I thought several of the figures from Dr. Mikel’s talk about

where food is wasted were very informative, so I’ve included them below: